<>Blanc-Labo S.A. your laboratory equipment specialist

Stackable shaking incubators

We offer a very wide range of shaking incubators (“shaking incubators” or “shakers” or “orbital shakers”) for all types of applications: microbiology, culture of plant, animal and human cells. Our shakers are manufactured by Labwit which has more than 20 years of experience with these products, the range of which is expanding from year to year. Labwit manufactures more than 1000 shakers per year.

All the options you need for quality work are available: controlled temperature, PID-controlled humification, infrared sensors for CO2, orbital (or lateral) agitation, alarms, data recording, fixing accessories, LED lighting, sterilization UV, remote control and piloting, password protection, etc.

Simple and very durable, Labwit shakers are completely comparable to the best products from Kuehner or Infors, for an attractive price.

They are guaranteed for 24 months

Share

The range

| Model | Description | Capacity | Velocity | Temperature | Technical sheet | Price | Cart |

|---|---|---|---|---|---|---|---|

| ZWYR-293G |

Incubateur agité "Premium Compact". Agitation orbitale de 1 à 50 mm ajustable. |

120 | 30 à 300 rpm | Amb-15°C à +60°C |

|

|

|

| ZWYC-D2401 |

Incubateur agité "Premium Large". Agitation orbitale de 1 à 50 mm ajustable. |

190 | 30 à 300 rpm | Amb-15°C à +60°C |

|

|

|

| ZWYC-290A |

Incubateur agité "Ultimate-Cell". Agitation orbitale de 1 à 50 mm ajustable. |

257 | 30 à 300 rpm | Amb-15°C à +60°C |

|

|

|

ZWYR-293G

Description

Incubateur agité "Premium Compact". Agitation orbitale de 1 à 50 mm ajustable.

Dim. du plateau (50x40 cm). Empilable jusqu'à 2 unités.

Capacity

Velocity

Temperature

Technical sheet

ZWYC-D2401

Description

Incubateur agité "Premium Large". Agitation orbitale de 1 à 50 mm ajustable.

Dim. du plateau (80x43 cm). Empilable jusqu'à 3 unités.

Capacity

Velocity

Temperature

Technical sheet

ZWYC-290A

Description

Incubateur agité "Ultimate-Cell". Agitation orbitale de 1 à 50 mm ajustable.

Dim. du plateau (85x45 cm). Empilable jusqu'à 3 unités.

Capacity

Velocity

Temperature

Technical sheet

Simple and durable: direct drive from 30 to 300 rpm. Orbital from 1 to 50mm continuously. Brushless motor guaranteed without vibration

Light configurable as you wish

C02 precisely controlled in the range of 0 to 20%

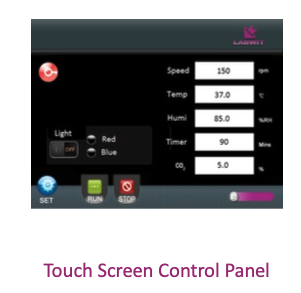

Touch screen and very intuitive software

Door control by password

UV sterilization to avoid cross-contamination

Swing deck slides forward on 2 rails for easy loading

IQ, OQ, PQ qualification on request

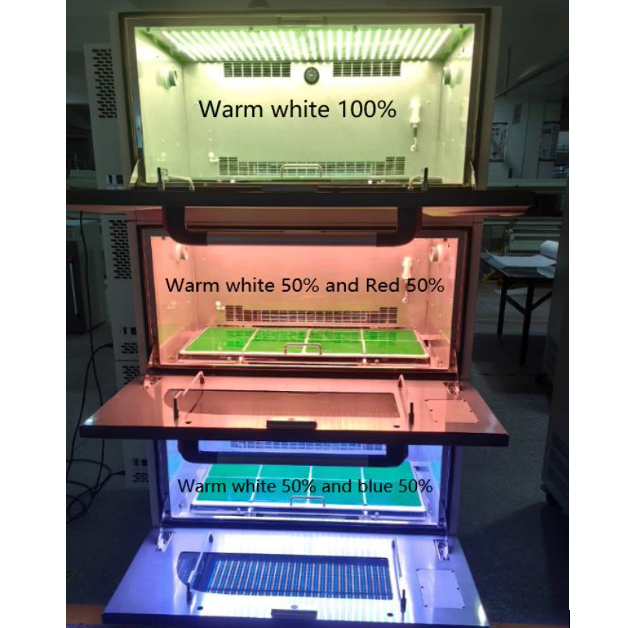

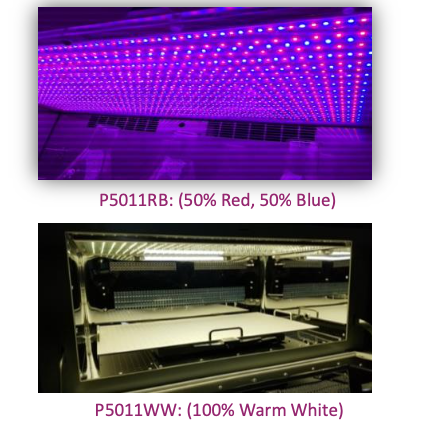

Tower of 3 ZWYC-290A with 3 different sets of LEDs

ZWYR-D2403: tower of 3 stacked D2401s

Tower of 2 ZWYC-290A

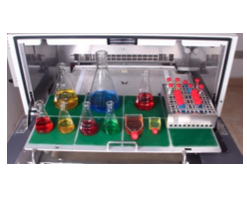

ZWYR-290A opened and loaded. Plain tray with sticky stuffs

ZWYR-D2401 on its support

ZWYC-293- Compact , stackable

Intuitive touchscreen

Integrated: Complete information is available at your fingertips. The screen panel clearly shows all basic operational parameters, such as temperature, speed and timer; as well as optional settings, for example, humidity level and CO2 concentration on a single page.

User-friendly: Easy-to-use graphical user interface with icons and pop-ups, making it easy to intuitively change operating parameters, even multiple set points in programmable mode.

Intelligent: The self-diagnosis alarm system monitors all functions and settings and prompts for errors, which are clearly indicated on the touch screen.

Direct drive stirring system

The innovative direct drive system ensures smooth and reliable orbital stirring motion with a speed between 30 and 300 rpm, even under unbalanced or maximum load on the stirring plate.

To achieve maximum flexibility for all applications requiring an optimized oxygen transfer rate, the stirring diameter can be continuously adjusted from 1 to 50 mm.

Long-life brushless motor provides constant, vibration-free stirring motion, maintenance-free and low heat emission.

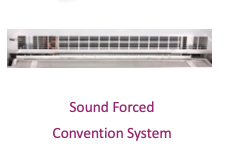

Excellent temperature control system

The solid polyurethane envelope optimizes the insulation of the room. Combined with the air circulation system and PID controller, it ensures evenly distributed airflow as well as precise and uniform temperature control throughout the chamber.

Its cooling system with CFC-free refrigerant and automatic defrost system ensures long-term stable operation at temperatures as low as 4°C, or 15°C lower than ambient temperature.

The microprocessor controller provides unmatched versatility by allowing users to create a custom program (with up to 9 segments, with cycles) to automate function parameter changes.

The tray slides forward for easy loading

Chamber capacity of 257L

The chamber is one of the largest in its range and can hold up to 32 500 ml Erlenmeyer flasks when the regular stirring plate (#P6023) and sticky mats are used.

The traditional pre-drilled stirring plate (#P6022) with dedicated holes for attaching vial clamps is also available. The maximum load of the stirring plate can reach 25 kg in total.

With an effective interior height extended to 425mm, the unit's chamber is still compatible with 5000ml bottles, even when LED lighting is installed.

See maximum capacity of the different Erlenmeyer flask clamps on the technical sheet

Direct injection humidification system

Humidity is important for long-term cell cultures with flasks as well as when microplates are used. The active controlled humidification system can effectively reduce evaporations during cultivation, preventing samples from drying out.

The Ultimate-cell humidification system includes direct steam injection at 140°C into the chamber and active PID control with a quality humidity sensor for optimal measurement accuracy.

Advanced CO2 control with infrared (IR) sensor

Effective control of CO2 concentration is essential for mammalian and algal cell cultures. The CO2 concentration is regulated between 0 and 20% to maintain the pH value of the solution medium at a healthy level.

Labwit integrates a single-beam, dual-wavelength IR CO2 sensor, which ensures superior performance and accuracy in situations where temperature and humidity fluctuate rapidly, such as when the door is opened frequently.

LED lighting: fully customizable

Ultimate-cell can be equipped with LED lighting panel for cultivation of phototrophic organisms, such as plant cultivation, algae, etc.

The light panels are available in warm white and blue and red, with a light intensity of up to 400 μmol/(m2*s ). Even distribution of light on the stirring plate. It is possible to mix colors and adjust the light power.

Easily programmable for day and night simulations. With a height of 10mm, the light panel minimizes the impact on the usable internal height above the stirring plate.

Cross-contamination control

UV sterilization: The UV sterilization system is isolated from the samples. It sterilizes the chamber air in the rear wall of the chamber to maintain contamination-free conditions in the chamber.

Easy to clean room. The bottom of the chamber is designed to collect and drain excess water and liquid spills in the event of a bottle rupture through an outlet on the side.