<>Blanc-Labo S.A. your laboratory equipment specialist

Photo-bioreactors for algae

You can configure your fermenter/bioreactor by clicking on this link –>

Our fermenters are manufactured by Bailun Technology, a fermenter manufacturer based north of Shanghai.

Bailun started 22 years ago as an INOX sheet metal manufacturer to manufacture tanks of all sizes for the food industry. Then they diversified 15 years ago into the manufacture of fermenters, first simple (for brewers for example), then more technical for the pharmaceutical industry and biotechs.

Their know-how in terms of welding and working with stainless steel is a real advantage for customers.

Furthermore, for 5 years, Bailun has chosen to completely review its product range to integrate critical components from European or US brands. In particular by redeveloping the control software on a SIEMENS S7 hardware and software platform.

In doing so, Bailun has had great success in recent years in Asia, Latin America and Eastern Europe with its fermenters.

BLANC-LABO has been installing and maintaining Bailun fermenters since 2019.

Share

The range

| Model | Technical sheet | Price | Cart |

|---|---|---|---|

| Benchtop photo-bioreactor: 1 to 10L |

|

|

|

| Stainless steel photo-bioreactor: from 10 to 5000L |

|

|

|

| Multiple photo-bioreactors: 1 to 10L, up to 24 in parallel |

|

|

|

Benchtop photo-bioreactor: 1 to 10L

Technical sheet

Stainless steel photo-bioreactor: from 10 to 5000L

Technical sheet

Multiple photo-bioreactors: 1 to 10L, up to 24 in parallel

Technical sheet

Tailor-made manufacturing

Integrated stainless steel workshop. Great flexibility

PLC SIEMENS S7. Software easily modifiable on request.

European or US critical components: good maintainability

Short delivery times

Installed and maintained by Blanc-Labo

A very wide range: from 5 to 5000L, multi-stage, parallel, bacteria, animal cells, plant cells, algae, mechanical or magnetic stirring...

Stainless steel control unit

Your pilot fermenter has a dedicated control unit on which the pumps, mass flows, and the control screen are grouped.

It is manufactured entirely in stainless steel by Bailun Technology in their integrated workshop. This allows us to adapt very quickly to your needs.

The fermenter is equipped with sensors and actuators from mostly Western brands, to facilitate its evolution and maintenance over time in France and Switzerland.

It is mounted on a “skid” at the factory, which is FAT tested before shipment. When it arrives on your site, simply connect it softly to the utilities to start commissioning.

Siemens S7 PLC

The fermenter is controlled by a Siemens Siematic S7 automaton

It is a stable and universal PLC, suitable for a variety of automation applications, especially for manufacturing process control. It is easy to network; it is the control unit of your fermenter.

You can therefore either display on the 10'' touch screen present on the unit all the information present in the software, or on a remote computer (option not encrypted in this offer): transmission of process data, visualization process, recorded samples, process parameters, etc.

And also benefit from all the standard peripherals offered by Siemens to integrate your fermenter into an internal industrial network.

The Siemens automaton makes it possible to exchange data in Profinet or OPC-UA with a SCADA type supervisor

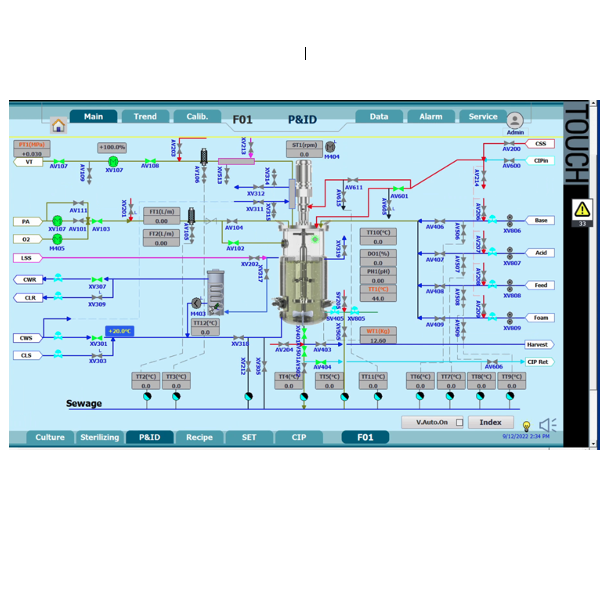

SCADA type main screen

Control software

The control software is built on a SIEMENS S7+ FORCE CONTROL base.

It therefore allows great scalability over time if your needs change.

It adapts to many actuators and sensors of various brands, which guarantees the scalability of the fermenter according to your needs over time.

The software is in English (FR optional).

The main screen is an ergonomic synoptic which allows you to easily view the status of the fermenter and all the valves at a given moment (SCADA type)

As standard, all the most common features are installed in the software:

Process control: either manual or software-driven depending on your recipes

The software can control all the actuators (rotameters, pumps, agitation, aeration, heating or cooling) using the rules that you establish and the values read on the various sensors.

You can choose PID or continuous type logic

Cascading laws are possible

User and password management

Sensor Calibration

Visualization by synoptic of the instantaneous state of the actuators and sensors

Alarms

Storage and export of data for each batch

Semi-Automation of the process thanks to the creation of cascading laws.

Peristaltic pumps (up to 7)

Your fermenter is equipped with WATSON MARLOW peristaltic pumps.

The model varies to adjust the flow to the size of the fermenter.

These pumps operate either manually or automatically controlled by the software.

Most often 4 pumps are mounted on our fermenters for acid, base, anti-foam and feed.

But you can add other pumps, for example to do an online analysis, a continuous process, operation in turbidostat mode, etc.

Mass Flow Controller

Incoming gases: Mass Flows Controllers and rotameter

The fermenter is equipped as standard with a rotameter for each incoming gas.

As well as one or more “Mass Flow Controllers” manufactured in Europe: Most often Buckert or Vögtlin brands

Incoming gases are sterile: filter and valve can be sterilized in line.

The software allows to manage cascades in correlation with dissolved oxygen (pO2)

Ventilation in VVM is adjusted according to your specifications.

The Mass Flow model is chosen together (identical price) after your order during the product detail definition phase.

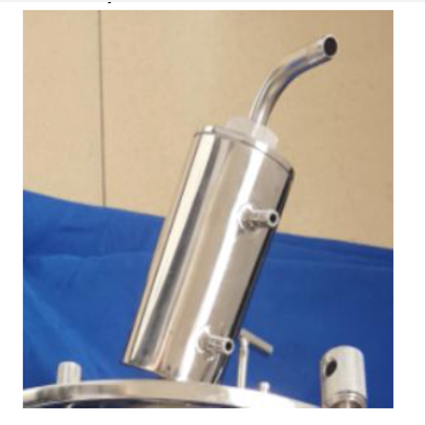

Outgoing gases: condenser and sterilizable filter

A condenser is positioned on the outlets of the fermenter. It is equipped with an in-line sterilizable HEPA filter. The relief valve is software controlled to provide protection from the outside and inside.

The integrity of the filter is checked in-situ.

The condenser is specially designed to prevent the accumulation of liquid and bacteria.

The condensate drain valve is manually controlled.

Outgoing gas analyzer

Outgoing Gas Analyzer

The outgoing gas analyzer (optional) is a GXH-3011N manufactured by HUAYUN Instruments. Several versions available depending on your needs.

The analyzer is in a box positioned next to the fermenter.

This instrument measures for a given gas the infrared radiation (NDIR) and its selective absorption of the infrared band of a particular wavelength, the absorption depends on the concentration of the measured gas.

The instrument can continuously measure a variety of other gases in the gas mixture online: CO, CO2, CH4, NO, SO2, NH3. It is used for example in petroleum, chemical, metallurgy and other industrial controls. Also for determining the gas content in agriculture, health care and universities and other research.

RQ measurement

It is possible to add RQ analysis software as well as a dedicated PC. The RQ measurement is made continuously on the PC (not on the Siemens PLC)

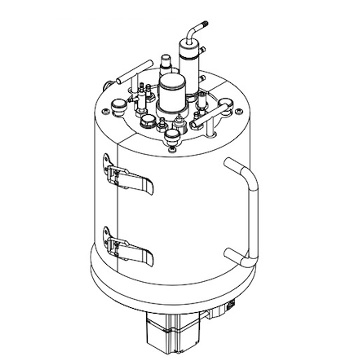

Double skin glass tank

The fermenter tank made by Bailun is made of double-walled glass. It is surrounded by a steel shell which holds the LEDs and protects the user from the intense light generated by the device.

Stainless steel cover and support

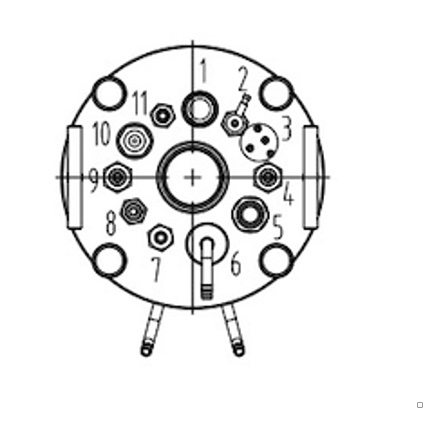

The 316L stainless steel cover is equipped as standard with 12 ports of varying diameters:

The attached image is for illustrative purposes only.

The cover is finalized on plan, according to your needs, no later than 7 days after your order, and before production begins.

Impeller

Mechanical stirring

In most cases, the engine is placed at the top. It is also possible to have stirring with motor at the bottom, or magnetic stirring.

The standard rotation speed (50-700 rpm +/- 0.5%) can be increased on request.

The motor axis is very rigid and allows use without long-term deformation. The engine gasket is most often made by John Crane in the USA.

All types of agitators (Rushton, marine, etc.) are available. They can be positioned on the motor axis according to your needs. 4 removable deflectors are offered as standard.

Sparger

Aération dans la cuve

En standard un bulleur en anneau est proposé. Vous pouvez choisir d'autre formes lors de la définition de détail de votre fermenteur.

PT100 probe

Sensors in the liquid phase: temperature probe

Temperature control is performed with a pT100 probe:

This controls the heating of the double jacket thanks to an electrical resistance included in the control unit or the steam valve (depending on the model).

Cooling is done by circulating city water, or a recycled water circuit via a cryostat supplied as an option.

Temperature control range: Mains water temp° +5°C. at 65°C, +/- 0.2°C

Display range: 0 to 150°C, +/- 0.1°C

pO2-Sensor

Sensors in the liquid phase: dissolved oxygen ( pO2)

The pO2 electrode is made in Switzerland. The pO2 value is controlled in association with speed, replenishment (feed), airflow (if configured) and other parameters.

Control range: 0~150%, ±3% fermentation process sequence control (according to fermentation time, automatic variable control DO, at least 10 steps)

The pO2 sensor is used to control recipes in cascades.

pH probe

Sensors in the liquid phase: pH

Temperature sensor made in Switzerland, very stable, with intelligent PID control for high control accuracy.

The electrode can be sterilized.

- pH electrodes and wires made in Switzerland

- Display range: 0.00~14.00±0.01,

- Auto control range: 2.00~12.00±0.02

- Online detection,

- Automatic alarm

Anti-foam probe

Sensors in the liquid phase: anti-foam probe

The anti-foam electrode detects the level of foam in the tank, and triggers the anti-foam product addition pump.

LED lighting

Each tank is illuminated by a belt of Philips brand LEDs housed in a stainless steel frame which is easily removable with 2 metal clips. FPCB type LED strips consume 6 or 8W/mL (depending on the density of LEDs imposed by your specifications and the size of the tank). There are between 60 or 80 LEDs per linear meter. They have a lifespan of 20,000 hours and operate at 24V. The length of the LED strips inserted into each fermenter is adjusted to deliver the required intensity.

Intensity: on request. Up to 750 micromoles/m2/s

Color: your choice at the time of your order: Warm White (3000K), Neutral White (4000K), Cold White (6500K). Or mixing.

Spectrum: CRI>80

The light is controlled from the main interface. It can be regulated on a scale of 0 to 7.

3L photo-bioreactor

Photo-bioeractors: 5 x 1L

3L photo-bioreactor. Magnetic stirring