<>Blanc-Labo S.A. your laboratory equipment specialist

Stainless steel pilot freeze dryers

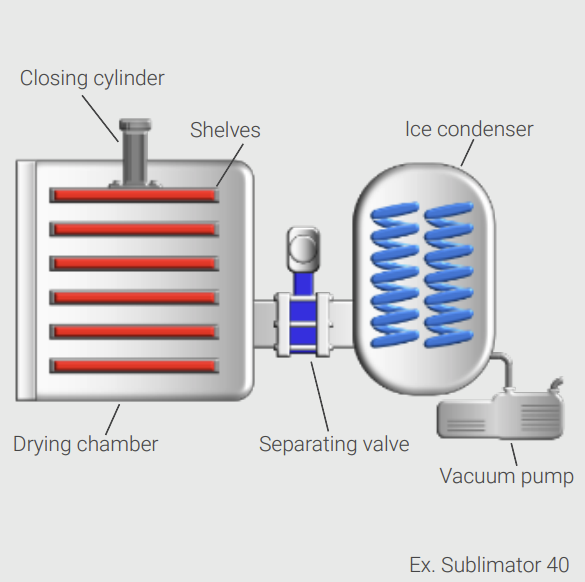

Pilot freeze dryers are characterized by the fact that this equipment can be adapted with a wide variety of different options. Freeze dryers of this type have both a separate ice condenser and cooling and heating shelves. The shelving system is available with an automatic closing and neutral gas closing device.

These systems are suitable for both bulk and bottle drying.

In addition, there are different adaptation possibilities for particular installation situations, such as in laboratories or pharmaceutical areas. Depending on your needs, the freeze-drying surface can be up to 2.70m².

These are equipment with 2 chambers, controlled by an industrial PLC (Siemens or Mitsubishi). They can be manufactured according to GMP standards if necessary.

They are available with many options, including CIP (Cleaning In Place), SIP (Sterilization in Place), and automatic closure of vials under an inert atmosphere.

See here the presentation video of the ZIRBUS pilot freeze dryers -->

See how automatic vial closure works -->

Zirbus has been manufacturing a very wide range of freeze dryers of all sizes for over 30 years.

Designed around a bank of proven components, Zirbus freeze dryers are fully configurable according to your needs, while remaining affordable. They are entirely manufactured in Germany in the vertically integrated Bad-Grund manufacturing unit.

It is this German quality, tailor-made, at a reasonable price, which has made Zirbus’ reputation.

Share

The range

| Model | Description | Technical sheet | Price | Cart |

|---|---|---|---|---|

| Sublimator 5 |

5kg/24h . Condensor -50° or -80°C max 6Kg. Shelves -60..+60°C. Tray or Vial drying. |

|

|

|

| Sublimator 15 |

10kg/24h . Condensor -50° or -75°C max 15Kg. Shelves -55..+60°C. Tray or Vial drying. |

|

|

|

| Sublimator 25 |

20kg/24h . Condensor -50° or -75°C max 25Kg. Shelves -55..+60°C. Tray or Vial drying. |

|

|

|

| Sublimator 40 |

30kg/24h . Condensor -50° or -75°C max 40Kg. Shelves -55..+60°C. Tray or Vial drying. |

|

|

|

Sublimator 5

Description

5kg/24h . Condensor -50° or -80°C max 6Kg. Shelves -60..+60°C. Tray or Vial drying.

Technical sheet

Sublimator 15

Description

10kg/24h . Condensor -50° or -75°C max 15Kg. Shelves -55..+60°C. Tray or Vial drying.

Technical sheet

Sublimator 25

Description

20kg/24h . Condensor -50° or -75°C max 25Kg. Shelves -55..+60°C. Tray or Vial drying.

Technical sheet

Sublimator 40

Description

30kg/24h . Condensor -50° or -75°C max 40Kg. Shelves -55..+60°C. Tray or Vial drying.

Technical sheet

All stainless steel pilot freeze dryers manufactured in Germany in the ZIRBUS integrated workshop.

Rectangular chambers to save space

Programs (up to 20) fully configurable by the user

Can be integrated into a wall (clean rooms)

Shelves regulated in temperature (-40° or -55° depending on model at +60°C)

Device for closing vials under neutral gas

SIP: In-situ sterilization (steam or H2O2) and cleaning (CIP)

GMP versions are available

Sublimator 25

Sublimator 5

Sublimator 50 integrated into the clean room wall

Sublimator 40, closed door

Sublimator 25 from front

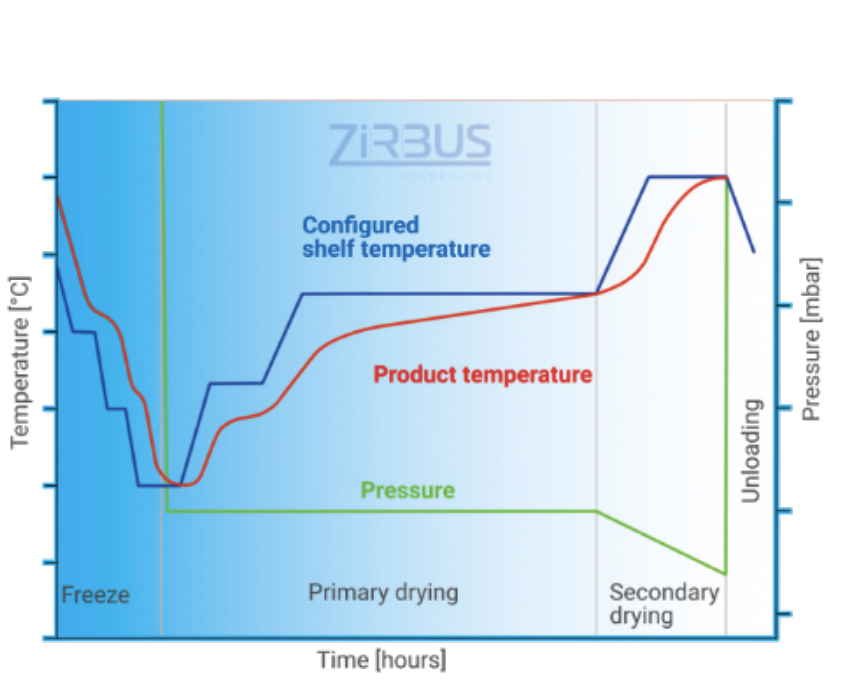

Fine management of the 3 phases of freeze-drying: freezing, primary and secondary lyo

CIP: spray nozzles

Isolator/glove box sterilely coupled to a Sublimator 40

The shelves are: temperature regulated, mobile and adjustable in spacing

A pilot-operated valve separates the chamber from the condenser

The condenser is visible on the front

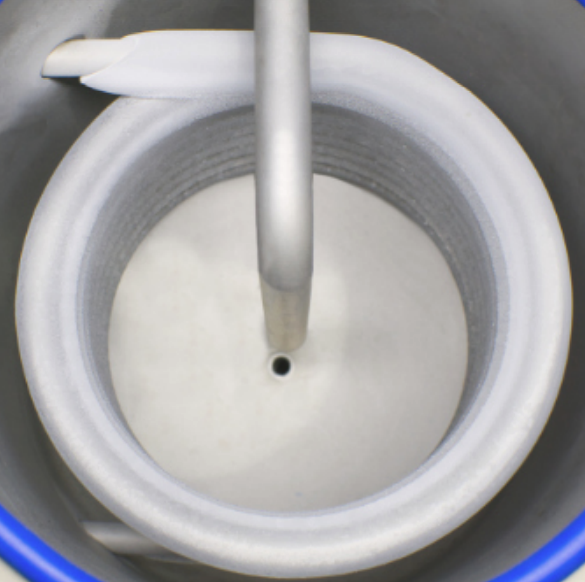

CIP (Cleaning in Place)

Spray nozzles mounted in the chamber and condenser ensure intensive cleaning.

SIP (sterilization in place) (from sublimator 15)

The chamber and condenser are designed as pressure vessels, so in-place steam sterilization is possible. Alternatively, H2O2 is also possible.

Compliance with GMP-FDA rules

Taking into account the guidelines, the systems meet the highest production requirements in compliance with clean room standards. The exact requirements are defined and implemented with you.

Temperature-regulated stainless steel shelves

For uniform and rapid temperature distribution, the shelves are flooded with brine oil.

Closing device for vials

The shelves can be automatically moved together after the drying process to vacuum seal the vials. Optimal conservation.

Air or water refrigeration system

Depending on the installation site, we can design the refrigeration systems to be air or water cooled.

Wall mounting (gastight)

The front of the device is installed gas-tight in a wall. This allows the service area to be separated from the production area.

Waterproof, oil-free vacuum pump

If organic solvents are present, it may be helpful to use an oil-free vacuum pump.

Insulator-Glove box connection

Units can be connected to isolators via a connection flange. Special designs are also possible.

Versch control systems, SCADA visualization

We offer a variety of different visualization and documentation systems.

EX ATEX protection version, solvent discharge

If explosive gas mixtures are present, the systems can be equipped with explosion protection.