<>Blanc-Labo S.A. your laboratory equipment specialist

Horizontal autoclaves HST

Zirbus has been manufacturing a very wide range of autoclaves of all sizes for more than 35 years.

Designed around a bank of proven components, Zirbus autoclaves are fully configurable to your needs, while remaining affordable. They are entirely manufactured in Germany in the vertically integrated manufacturing unit in Bad-Grund.

It is this German quality, tailor-made equipments , at a reasonable price, which has made the reputation of Zirbus.

Zirbus products are delivered, according to your needs, with all the documentation and qualification and validation operations required by your type of industry (pharmacy, medical, laboratories, etc.): GMP, FDA, etc.

Blanc-Labo has been installing and maintaining Zirbus equipment for 33 years.

Share

The range

| Model | Chamber Vol. (L) | Int. dim ( W x H x D ) mm | Technical sheet | Price | Cart |

|---|---|---|---|---|---|

| HST series 4 (446, 466 or 469) | 150 ... 305 L | 450 x (500 ...700) x (670 ...970) |

|

|

|

| HST series 6 (666, 669, 6612, 6616, 6618) | 304 ... 805 L | 650 x 700 x (670 ... 1870) |

|

|

|

| HST series 8 (866,869,8612,8616,8618) | 370 ... 1033 L | 650 x 850 x (670 ... 1870) |

|

|

|

| HST production autoclaves ( 10H serie) | made-to-measure | upon specifications, up to 3100L |

|

|

|

HST series 4 (446, 466 or 469)

Chamber Vol. (L)

Int. dim ( W x H x D ) mm

Technical sheet

HST series 6 (666, 669, 6612, 6616, 6618)

Chamber Vol. (L)

Int. dim ( W x H x D ) mm

Technical sheet

HST series 8 (866,869,8612,8616,8618)

Chamber Vol. (L)

Int. dim ( W x H x D ) mm

Technical sheet

HST production autoclaves ( 10H serie)

Chamber Vol. (L)

Int. dim ( W x H x D ) mm

Technical sheet

German manufacturing.

Made entirely of stainless steel for longer durability and easy cleaning

A very wide range: 13 models as standard, with 1 or 2 doors (passage doors)

Models with special dimensions are also available upon request.

Rectangular rooms save space (see appendix)

7 versions and many options to meet your needs

Especially GMP versions

Qualification IQ,OQ,PQ

Spare parts are available for 10 years

You can configure your HST autoclave using this link

Horizontal autoclave HST 14x10x14 2 doors thru

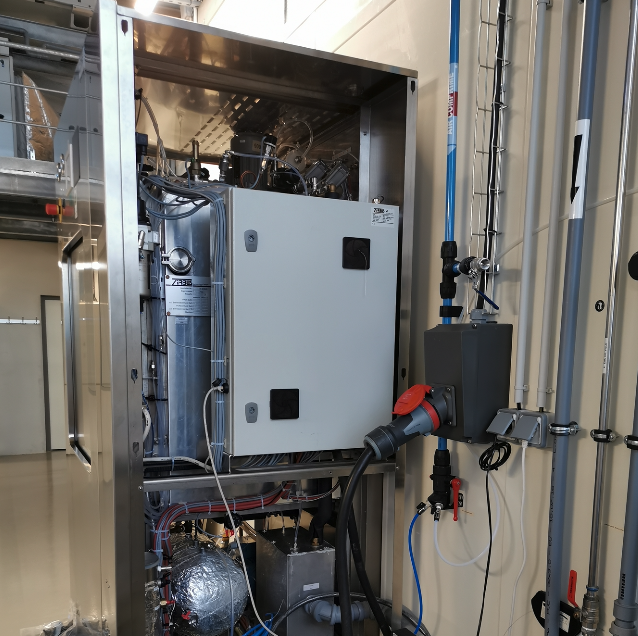

HST 8x6x6 horizontal autoclave with adjustable height trolley

Autoclave HST 4x6x6

HST6x6x12. Interior view, top of the tank

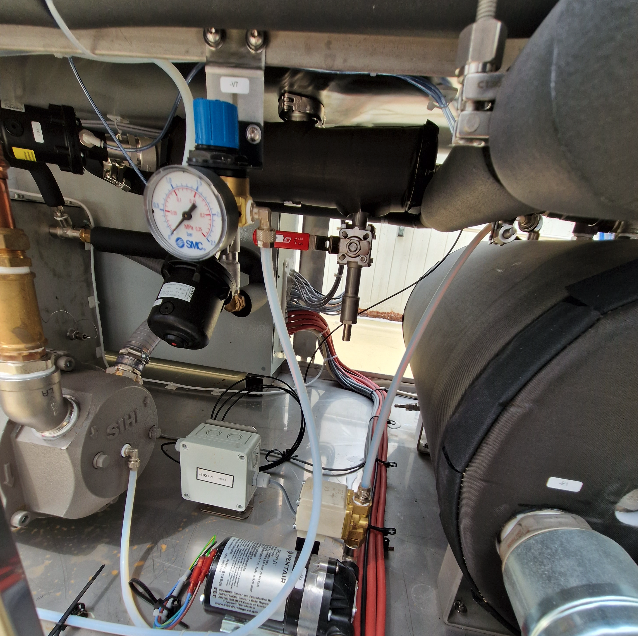

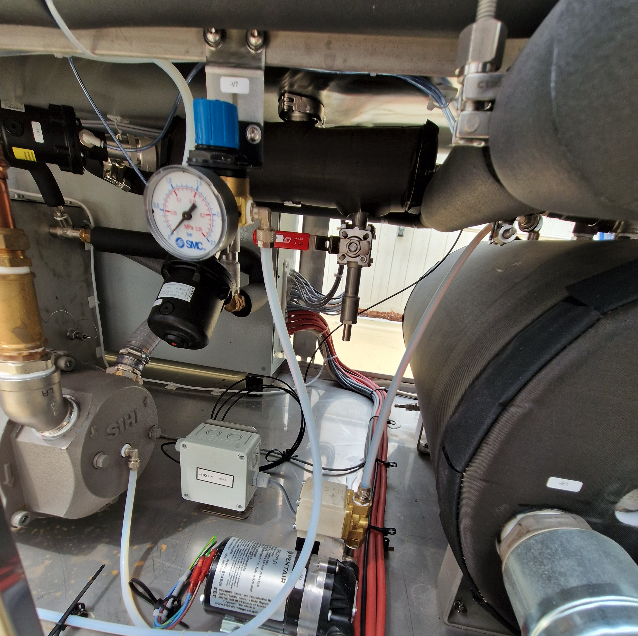

HST6x6x12. Interior: under the tank

HST 6x6x12. Steam generator

HST6x6x6 crossing. dirty side screen.

HST 6x6x6 crossing. Dirty side.

HST 6x6x6 crossing. 4-tier loading cart.

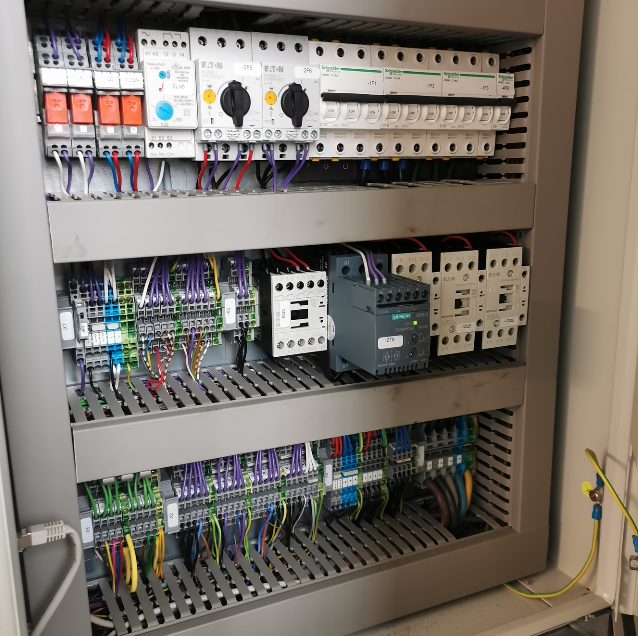

HST 6x6x12. Electrical box

HST6x6x12. interior under the tank

HST 6x6x6 . PQ Qualification

HST 6x6x6 crossing. Dirty side

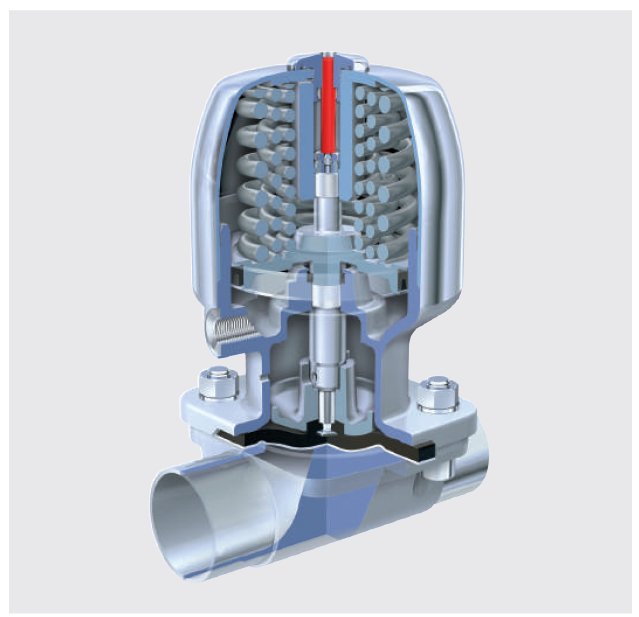

HST6x6x6. GMP steam valve

HST6x6x6. Front face printer

HST production 20x12x16

BASIC LAB version: recommended for simple needs. Sterilization of liquids or solids without drying. Equipment: steam generator and automaton with SteriTouch Control software

DRY LAB version: recommended for the sterilization of solids (waste, instruments) with imperative drying. Equipment: steam generator, automaton with SteriTouch Control software, vacuum pump

QUICK LAB BASIC version: recommended for sterilizing liquids with rapid cooling. Equipment: steam generator, automaton with SteriTouch Control software, cooling with internal mixing fan.

QUICK LAB version: recommended for the sterilization of non-infectious solids (waste, instruments) and liquids with imperative drying and rapid cooling. Equipment: steam generator, automaton with SteriTouch Control software, vacuum pump, internal mixing fan

QUICK LAB ADVANCED version: recommended for the sterilization of non-infectious solids (waste, instruments) and liquids with imperative drying and rapid cooling. Suitable for agars and liquids in closed containers to avoid spillage during cooling. Equipment: steam generator, automaton with SteriTouch Control software, vacuum pump, internal mixing fan, back pressure with air-steam mixture

SAFE LAB version: recommended for the sterilization of INFECTIOUS solids (waste, instruments) of type S2, with imperative drying. Equipment: steam generator, automaton with SteriTouch Control software, vacuum pump, ALF filter on the air outlet

COMPLETE LAB version: recommended for the sterilization of solids (waste, instruments) and INFECTIOUS liquids of type S2, with imperative drying and rapid cooling. Equipment: steam generator, automaton with SteriTouch Control software, vacuum pump, internal circulation fan", ALF filter on the air outlet

Validation DQ,FAT,IQ,OQ,PQ,SAT

DKD Calibrations

STERILOG documentation software on industrial PC. For reading and archiving data from each batch in .pdf or .csv on PC via the RJ45 Ethernet port.

Front thermal printer

Screenshot on 10-channel PC to GMP and FDA CFR21 part11 standards

6-channel GMP printer

Independent temperature measurement according to EN285. A 3rd temperature probe allows data to be recorded independently of the 2 probes that control the device.

Manufacture of the autoclave according to GMP standards

CFR21 user management with audit trail

Connection to the building's steam generator (no steam generator in the autoclave in this case)

BIOSEAL. To install a crossing autoclave between 2 clean and dirty rooms

AIR-STEAM mixture. For sterilizing blisters or closed liquid containers

Kit to save water (heating mantle and vacuum pump) by recycling

Rapid cooling by spraying (spray cooling)

Hot water sterilization (HWBV). For sterilizing large quantities of liquids or closed containers (canned goods for example)

Steam sterilizable incoming air filter

WIT test to ensure filter sterility

Valves controlled by programmable ramps to finely manage the rise and fall in temperature and pressure.

Special programs: ISO 4802, ATF filter, DURHAM

Vertical door

The autoclave is equipped with a fully automatic vertical door.

Low maintenance.

Maximum security.

Saving space in your lab

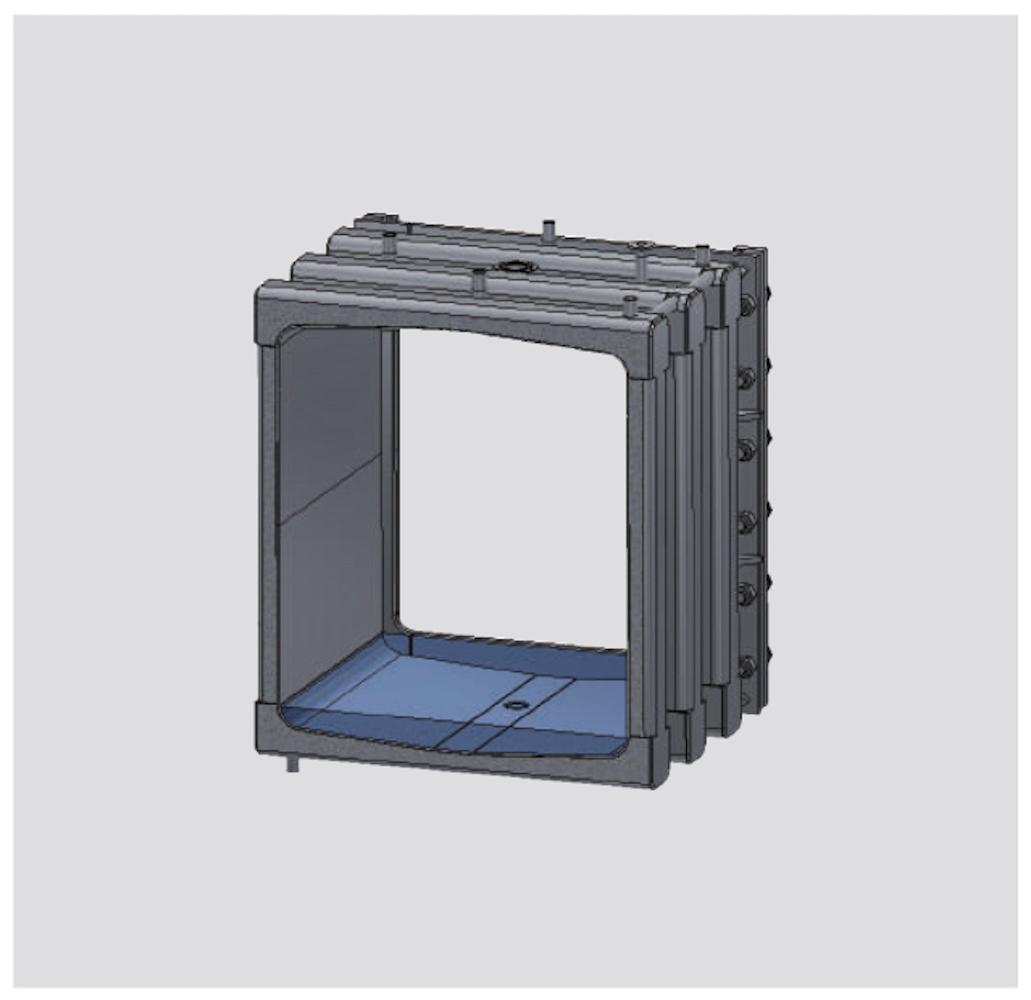

Chambre en Inox fabriquée en interne

Integrated manufacturing of the stainless steel chamber

Zirbus produces all the stainless steel sheet metal in-house, for greater flexibility.

The chambers are slightly inclined towards the evacuation of condensates to allow their complete drainage.

Rounded corners allow for easy cleaning.

The walls of the chamber are made of INOX 1.4404 (AISI 316L)

The double coat is in INOX 1.4571 (AISI 316 Ti)

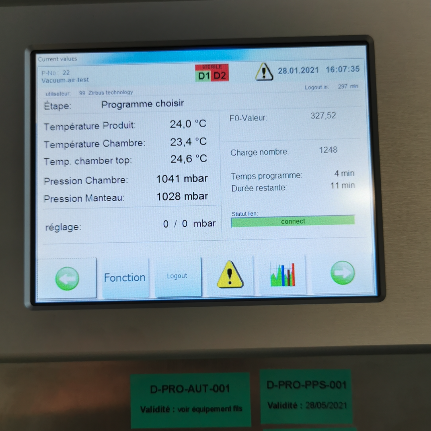

7" touch screen

The 7" touch screen allows control of the autoclave from the front panel.

This screen contains a PC which communicates control information to the PLC. The software is very comprehensive and easy to use. The data from each batch is stored in the autoclave and can either be printed or sent via the Ethernet port to a PC in .pdf or .csv format for archiving and/or analysis.

Transport and loading trolley

Transport and loading carts

They allow loading and unloading of the chamber effortlessly.

The height of the shelves can be easily adjusted.

A “docking” system makes it easy to position the load exactly in the axis of the rails.

Clean room compatible.

It is also possible to have a height-adjustable transport trolley.

Steam generator

Steam generator

All 13 HST models are equipped with a compact steam generator integrated into the autoclave body. It works with demineralized water to avoid the formation of non-condensable gases in the chamber.

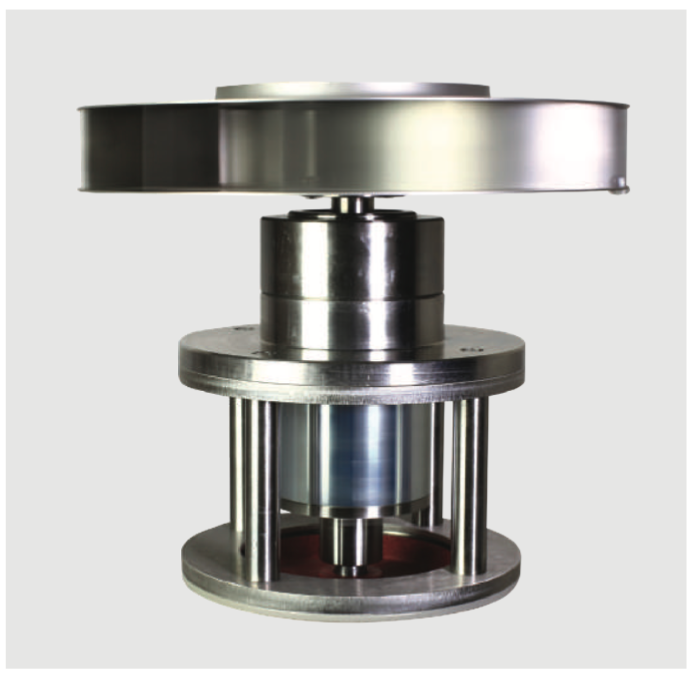

Internal air fan

Internal brewing fan

To shorten the cooling time, this fan circulates the air inside the chamber to bring it into contact with the walls which are cooled by the double mantle.

This option is necessary to avoid liquid overflows in containers closed with the DLGV function (air-steam mixture)

GMP compatible pneumatic valve

GMP manufacturing according to DIN ISO58950

All pipes are made of 1.4404 stainless steel, class H3

The valve diaphragms are in 1.4435

The interior of the chamber is sandblasted then electropolished (Ra<0.8mic, optional Ra 0.4mic)

No dead space in the pipes and valves in contact with the products to be sterilized.

Rapid recooling

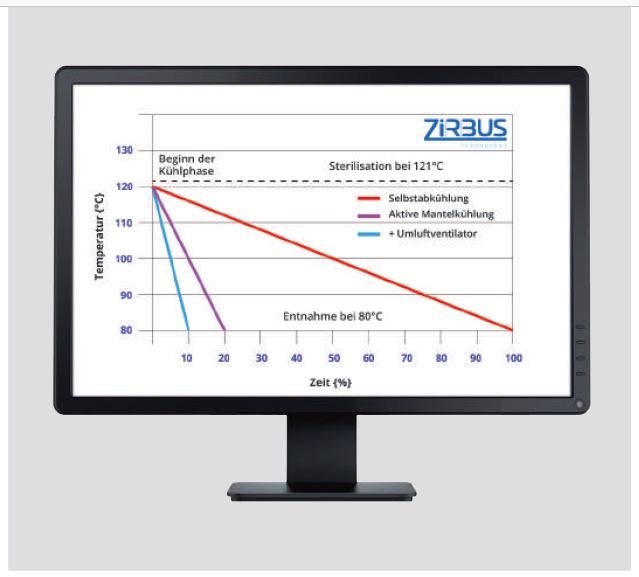

Rapid cooling

This option reduces cooling time by up to 80% compared to natural cooling.

Ideal if you want to do several cycles during the day with lots of liquids.

The pressure is regulated via the outgoing air filter

It is possible to connect the double coat to your chilled water circuit (option)

Pressure gauge on the front

High-performance liquid ring vacuum pump

A liquid ring vacuum pump allows you to completely remove the air contained in your products and replace them with sterilizing steam. You can choose between these "pre-vacuums" in one step (for liquids and glassware) or with successive pre-vacuums configurable by the user (for waste and instruments).

ALF filter pour S3/S3 labs

Outgoing air filter approved by RKI (Robert Koch Institute)

For the sterilization of products classified S2/S3, the outgoing air is directed to a filter which continuously sterilizes it (Tested according to RKI according to section 18 lfSG Infection Protection Act)

The base of the chamber is slightly inclined to direct all condensate to the condensate sterilization. 0.01 micron filter.