<>Blanc-Labo S.A. your laboratory equipment specialist

HDA type high pressure autoclaves

Entirely made to measure. Maximum temperature: 250°C. Maximum pressure: 20 bars. Chamber diameter from 300 to 1400 mm.

Zirbus has been manufacturing a very wide range of autoclaves of all sizes for over 35 years.

Designed around a bank of proven components, Zirbus autoclaves are fully configurable according to your needs, while remaining affordable. They are entirely manufactured in Germany in the vertically integrated Bad-Grund manufacturing unit.

It is this German quality, tailor-made, at a reasonable price, which has made Zirbus’ reputation.

Zirbus products are delivered, according to your needs, with all the documentation and qualification and validation operations requested by your type of industry (pharmacy, medical, laboratories, etc.): GMP, FDA, etc.

Blanc-Labo has been installing and maintaining Zirbus equipment for 33 years.

Share

The range

| Model | Chamber Vol. (L) | Main caracteristics | Technical sheet | Price | Cart |

|---|---|---|---|---|---|

| HDA (custom-made) | 60 à 5000 | Réalisé sur-mesure . Diam chambre de 300 à 1400mm. Pression maxi : 20bars. Temp° maxi :250°C |

|

|

|

HDA (custom-made)

Chamber Vol. (L)

Main caracteristics

Technical sheet

German manufacturing.

All stainless steel for greater durability and easy cleaning

Completely custom made

Dry or moist heat

Maximum pressure 20 bars

For electronics, automobiles, materials testing, pressure bonding, etc.

Spare parts are available for 10 years

HDA 200L, 180°C, 6bars

HDA 400L, 250°C, 8bars

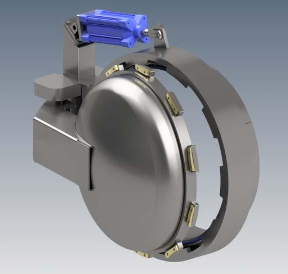

Door with bayonet safety lock

How an HDA Zirbus autoclave works

Zirbus HDA series autoclaves are high pressure autoclaves.

They are used in the food industry, industry and electronics.

These devices can operate with dry heat or saturated steam.

Dry heat operation:

The autoclave has a securely secured door and automatic opening/closing controlled by the automaton which manages the machine.

Once the door is closed, the temperature and pressure can rise or fall depending on the needs of the process.

The pressure is provided by an external air compressor which must be capable of raising the chamber to the maximum pressure required by the process.

The temperature is managed by electric heating elements integrated into the autoclave.

The autoclave can optionally be equipped with cooling by cold water coils.

In dry heat all the torques (Temperature, Pressure) are achievable, within the limits set by the resistance of the chamber.

The automation which manages the autoclave uses the air inlet and outlet valves, as well as the 2 temperature sensors and the pressure sensor, to follow the autoclaving cycles imposed by the user.

This mode of operation is particularly used in electronics, and for pressure bonding.

Saturated steam operation:

Operation is identical to the previous case, but the autoclave must be connected to a steam generator capable of increasing pressure and temperature to the maximum requested.

In this case the couples (temp°, pressure) follow physical laws: when pressure is imposed, the temperature results.

This mode of operation is particularly used in the food industry, or for textiles for example.

For heat treatments under pressure

Autoclaving up to max. 160°C / 5 bar

1. Autoclave chamber:

Construction: cylindrical chamber, horizontal

Material: stainless steel 1.4571

Chamber dimensions: Ø307mm x 600mm length

Chamber volume: 45 liters

Surface: passivated and hammered with glass beads

Max. Pressure: 6 bar

Max. Temperature: 160°C

Max. Operating pressure: 5 bar

Electric heating with a maximum speed of 5°C/min

Chamber connections: pressure relief, floor drain, probe connection

The chamber is manufactured in accordance with the European directive F. Pressure vessel DGRL 2014/68 / EU., as well as in accordance with the German standard AD2000.

Construction and pressure testing according to module H are included.

Insulation of the room with insulating wool, covered with an aluminum coat.

2. Bedroom door:

Model: round snap lock

Material: 1.4301 stainless steel

Surface: chemically passivated

Closing process: quick release bayonet closure

Complies with DIN and TRB safety standards.

3. Sealing system:

Silicone profile gasket

4. Heating system:

Internal heating system, continuously adjustable in 1°C steps

Up to max. 160°C,

400V / 50Hz connection

5. Recirculating fan: (option)

A recirculation fan is installed in the rear wall of the autoclave.

This ensures uniform temperature distribution in the room.

The drive unit is located outside the pressure vessel and the transfer is carried out by magnetic coupling.

Special air deflectors in the chamber ensure even temperature distribution.

6. Measuring Techniques:

1. Pressure sensor 0...10bar / 4...20mA

2. Temperature probe for the room

7. Control automaton:

Material: Mitsubishi FXN SPS

Operation: 7" color touch screen

Programs: 10 pcs.

Program structure:

Multiple temperature and pressure steps with holding times can be set for each program.

Display :

- Temperature heating system

- Temperature chamber

- chamber pressure

Function display:

- Alarms

- Overview of the current process

8. Safety devices:

- 10 bar pressure relief valve

- Pressure gauge 0 ... 10 bar

- Safety temperature limiter

9. Valves:

Pneumatic valves for:

- Pressure rise valve

- Pressure limiting valve